CONTEXT AND CHALLENGES OF THE BRAZILIAN CERAMIC TILE MARKET

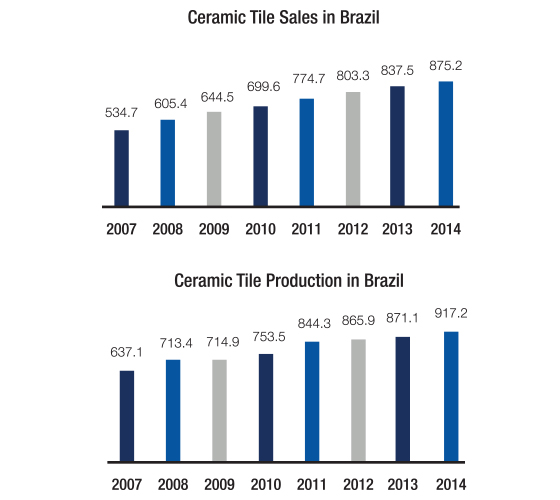

The Brazilian ceramic tile market is the second in terms of production and consumption in the world, and it stands out for the constant growth and increase in product variety. In the last 7 years, average production in Brazil grew over 5% a year, while the average growth of the internal market exceeded 7%, directing the focus of the companies to the internal market.

According to information by Anfacer (the National Association of Ceramic Tile Manufacturers), the Brazilian market is highly segmented, with 93 companies producing tiles, mostly originally family-owned companies.

Due to the high segmentation and competition, Brazilian companies started a trend toward professionalization and they started investing more in added value services for differentiation.

INTERNAL ENVIRONMENT

In this context of growth, our client knew how to seize the moment to boost sales, increasing its billing by 20% a year in the last 5 years, reaching the milestone of R$ 1 billion in sales. Today, the company is a market leader and a pioneer in terms of innovation in items and designs, with a production of over 30 million square meters.

To accompany such marked growth, the company also structured itself and it invested in production capacity, technology and portfolio. Moreover, new sales channels with personal attention and differentiated delivery services started being explored for increased profitability.

After these gains, the next step was to invest in developing an Integrated Distribution Model to overcome the new challenges derived from the large scale and the diversified sales channels, including its franchise network, with over 110 stores throughout Brazil.

Thus, we conceived the integrated logistical model that guarantees the best quality in product delivery and availability, with reduced costs, by moving inventory along with the logistical partners.

INTEGRATED DISTRIBUTION MODEL

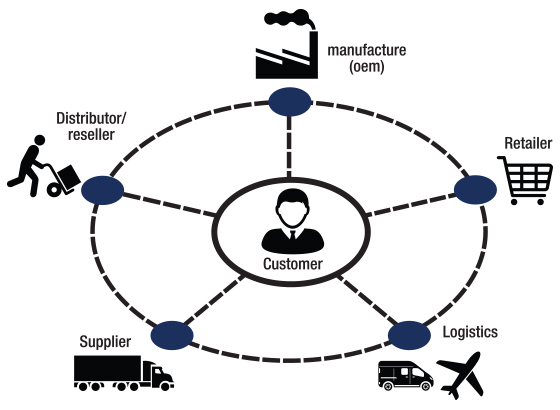

The distribution model designed for the company, sought to meet the needs of the most demanding ceramic tile Clients in the market, including improving quality and reducing lead times. For that purpose, the period of between the preparation and the new operation involved the development of 5 major fronts that were essential in the integration: partner management, OTD (order to delivery), stock replenishment, business policy and change management.

- A rigorous Partner Selection and Management is as important as the internal operation itself, since they often are in direct contact with the final customer, and they are responsible for the way the client perceives service quality.

- The main purposes of the (Order to delivery = OTD) activity is to understand the make up of the orders and the characteristics of the clients and to review the processes, rules, manuals and indicators to better adequate to the administration of the operation

- The Stock Replenishment process is responsible for optimizing the composition of the stock advanced, and therefore to reduce storage costs. This model requires not only a good restocking process, but also a rigorous and specific preparation for each situation

- The Business Policy offers significant opportunities of reducing costs for the client, and it shall be reviewed and adapted to maximize fiscal impacts and to reduce costs and taxes

- The Change Management process permeates all the activities that are required in the implementation, offering support and training to the stakeholders, preparing those who will be in charge of the continuity of the work after the completion of the project

Figure 1: Centralized Logistics

Figure 2: Integrated Logistics

Throughout the implementation of the new system, the main drivers of the company were reliability, efficiency and service management up to the final customer, which resulted in the reshaping of the focus, up to day a factory oriented one, to a new market focus, accompanying the product from production until the delivery at the customer’s home.

CONCEPTION OF A NEW MANAGEMENT

The implementation process of the new model mobilized 120 franchisees, 250 store managers, 1.200 salespersons, over 900 supplier collaborators and partners, and a project team of 45 people.

The new logistics incorporated new areas, processes, discussions and subjects that were previously inexistent in the company, including:

- Creation of a centralized restocking area, to guarantee the availability of the stock in accordance with the profile of each CD;

- Creation of a service unit in each distribution center, to act jointly in the management of the stock and the deliveries;

- Scheduling every delivery;

- End to end supply chain focus, monitoring deliveries up to the final customer vs an order-based focus until the order leaves the factory;

- Change of the collection model, from FOB to CIF;

- Adjustment of indicators;

- Preparation of policies and inventory levels.

Meanwhile, a new operation also originated surprises and unexpected results that needed to be adapted to the new reality, handled on a day-today basis in each of the fronts, and discussed every week by the project committee, in order to guarantee the adequate conduction of the project, while guarantying autonomy for a quick decision making at the team level.Through surveys and specific indicators, all the areas were aligned with the operation and were familiarized with the critical items that required attention.

RESULTS AND BENEFITS

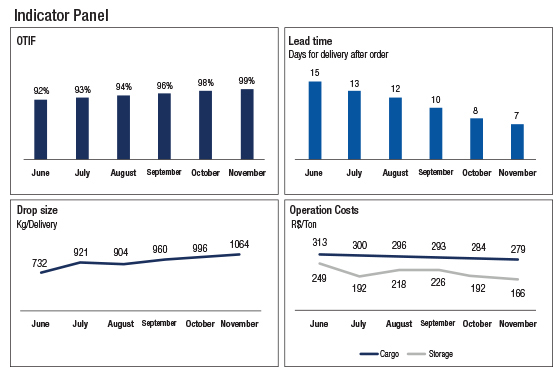

The results of the project are not limited to the reduction of delivery times (from 20 to 7 days), to improving the level of the service (from 94%, estimated at the factory door, to 98% when delivered to the final customer). After the start of the operation, sales grew 11 % compared to the previous year, while primary shipping costs were reduced by 15%.

Moreover, in addition to the improvement in indicators and costs, the client became a pioneer in the reduction of delivery times, using its own logistics as a competitive advantage to preserve its position as a leader in the ceramic tile market.