Background

An economic crisis, emerging competitors, demanding clients and a broad array of products make up this changing global market. Companies with complicated production processes, such as steel mills, petrochemicals, cement companies or energy companies that usually are found in the first link of the transformation chain are confronting huge challenges to be successful in their sphere. Since these companies have fixed assets with a high value and high operating costs, traditionally they have focused on minimizing operating costs by accepting large scale orders, maximizing the use of machines and minimizing inventory. The result is that full synchronization with clients that have ongoing operations to push sales and even negotiations to tolerate non-compliance is not achieved. For these companies, the price uncertainty and loss of sales caused by the recent crises have forced them to change their strategic direction to achieve greater synchronization with their clients. In companies where the cost has historically been the main indicator, this synchronization implies innovating and breaking paradigms.

The Problems

Efficient production chains with a high production cost seek to do production in long runs, with a limited number of products and deliveries to disparate clients. If changing the business model is what is wanted to deal with a market with shorter response times, high delivery reliability, a broader array of products and lower volume per order, investments in capacity and inventory may be required The question is: How much is it going to cost me? The cost of this strategy depends on an agreement between service and efficiency. Servicios Globales (global services) would like to evaluate whether your customer service may be improved and be profitable at the same time.

The Initial Situation

The Servicios Globales company has integrated manufacturing beginning with its raw materials and provides a B2B service, offering a broad array of products. Greater domestic and international competition and client dissatisfaction has caused a drop in sales and profits. Servicios Globales has an average response time of 7 weeks, which is competitive in the industry. Nevertheless, the source of complaints lies in the reliability of the stipulated delivery date and uncertainty in the offered period. Just 65% of the volume meets the deadline and 32% of the volume is shipped in a period from 8 to 24 weeks.

In companies, usually the production planning department assumes a large part of the responsibility for not meeting the client’s delivery deadline. The lack of synchronization with the business department, however, has a direct impact on this performance. At Servicios Globales, 26% of the volume captured by the sales people consists of rush orders with a requested delivery period that is sooner than the minimum production time.

Servicios Globales has a production process with multiple restrictions and bottle necks. The process is complicated and requires a great deal of energy. To take advantage of it, manufacturing is designed to produce in batches and long production runs. The production volume and the working capital used each day are high so the risk of having flow problems is high. Traditionally, this industry uses an order-based production plan to reduce inventory so they only accept high volume orders with material output times of greater than two months. Servicios Globales is intensive in using its capacity and, to take care of its clients’ needs, it operates using a hybrid system consisting of order-based production and creating inventory to be able to do long production runs, keeping operations at maximum capacity. The inventory level is set by the planning department, which takes into account a demand plan with 67% assertiveness. For Servicios Globales, improving customer service is vital if it wants to remain competitive.

Solution

To achieve its new goals, Servicios Globales needs to revisit its supply to clients and align its operations with the market. The service supply is the way a company would like to attend to the market. It is defined strategically and should be in alignment with the company’s market goals. The main elements are time, quality, and service. The clients need to be analyzed to identify similar segments where parameters may be established ad hoc to prioritize service. To segment the clients, business, operating, and strategic information needs to be compiled.

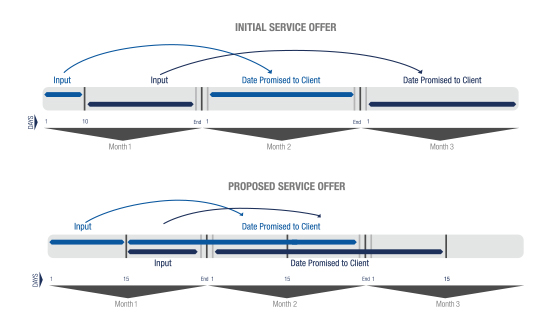

Since delivery reliability is the main source of dissatisfaction, the time involved in inputting, planning and promising delivery of a client’s order need to be evaluated. These are all components when offering a service. Servicios Globales asks its clients to place orders within a limited window of time and does its production planning in monthly cycles for all its clients. With these input standards, the order may stay open up to 4 weeks waiting for a production date. These operating guidelines impact the duration of the order, reduce the reaction agility related to the demand and foster non-compliance when faced with adverse market conditions (low demand). To offset the effect of exceptions and reduce unfeasible order stress, a suggestion was made to break down the planning time into two-week cycles without an input window. This allows for the client to input orders more flexibly, greater synchronization between production and the market, the same delivery deadline and greater reliability. This supply should be aligned with the business goals so they are prioritized based on client segmentation that considers revenue, the average monthly sales volume, and the sales channel as the primary variables.

The service model should be congruent with the capacity and should help synchronize business activities with the company’s operations. The supply strategy seeks to meet the service guidelines by executing operations at the lowest cost possible. This strategy is used to synchronize operations and the different areas such as production, warehousing, and distribution. Changes to the service supply force alignment of the supply chain and the areas involved. At Servicios Globales, maintaining the inventory turns out to be extremely costly. Proper inventory planning, however, can assure service levels for us and protect productions from changes in demand. An inventory replacement strategy was designed in the first production stages where product inventory with high turnover and low variability is able to be optimized, as well as order-based production for products with low turnover and high variability.

This solution encases different areas, including strategy management, service supply, business practices, order input and handling, inventory strategy, planning processes and production scheduling, and the operating processes for warehousing and distributing the product. For the change to last, the organizational structure and the management model need to be modified. Investments need to be made in new information technology tools, communications channels need to be set up to achieve synergies between the different areas and the operating parameters even need to be modified (e.g., production runs and product routing).

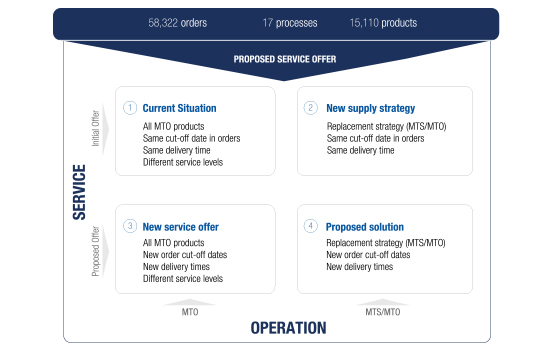

Simulation

To estimate the benefits and quantify the impact of using machinery and working capital, an operation was simulated with 4 scenarios using the optimization technique with mixed-whole scheduling of binary variables; where 17 production processes, 15,110 products and 58,332 client orders were modeled in daily cycles.

The simulation showed that operating the same way and maximizing the current resources is only able to increase the service level to 68% (+3%). In the same scenario, a service level of 79% may be reached if the inventory is increased by 55% (WIP / PT) and an investment is made in the production capacity for 6 processes. When the proposed solution was modeled (changes in inventory and service supply), it demonstrated that a service level of 85% can be reached by increasing the inventory 110% (which represents 21 days of coverage), but without investing in production capacity. This new way of operating allows for greater synchronization with the market and involves better use of the installed capacity.

Conclusion

With more competitive service, the number of clients, sales, and revenue per client are expected to rise (either due to a pricing strategy or sales of products with greater added value). For the Servicios Globales company, this means changing its market position and improving revenue. The proposed solution makes it possible to raise client fulfillment from 65% to 85% with a service supply that is attractive for clients and an inventory plan with strategic points to have a more flexible production chain. This solution does not require any investments in capacity and the projected inventory level could be reduced to improve the assertiveness of the prediction or by bringing in more flexible manufacturing technologies and techniques. The solution implies entering a transformation phase with involvement running from upper management down to the operating areas. This effort is mandatorily comprehensive and should transcend the organization to survive in the market.